Applications & Solutions

Taicron E, SE, SF Series

I. Exhaustion Dyeing

After the fabrics are prepared, the dyestuff and dyeing auxiliaries are moved into the dyeing machine. There are two methods recommended as follows :

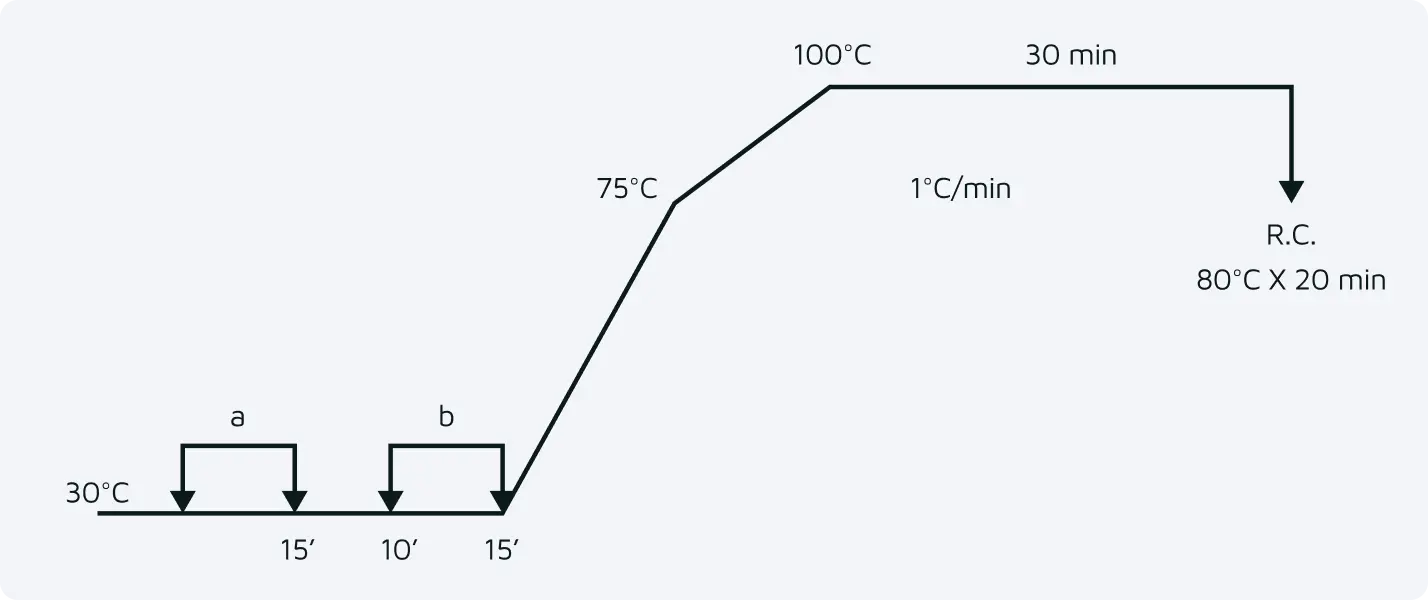

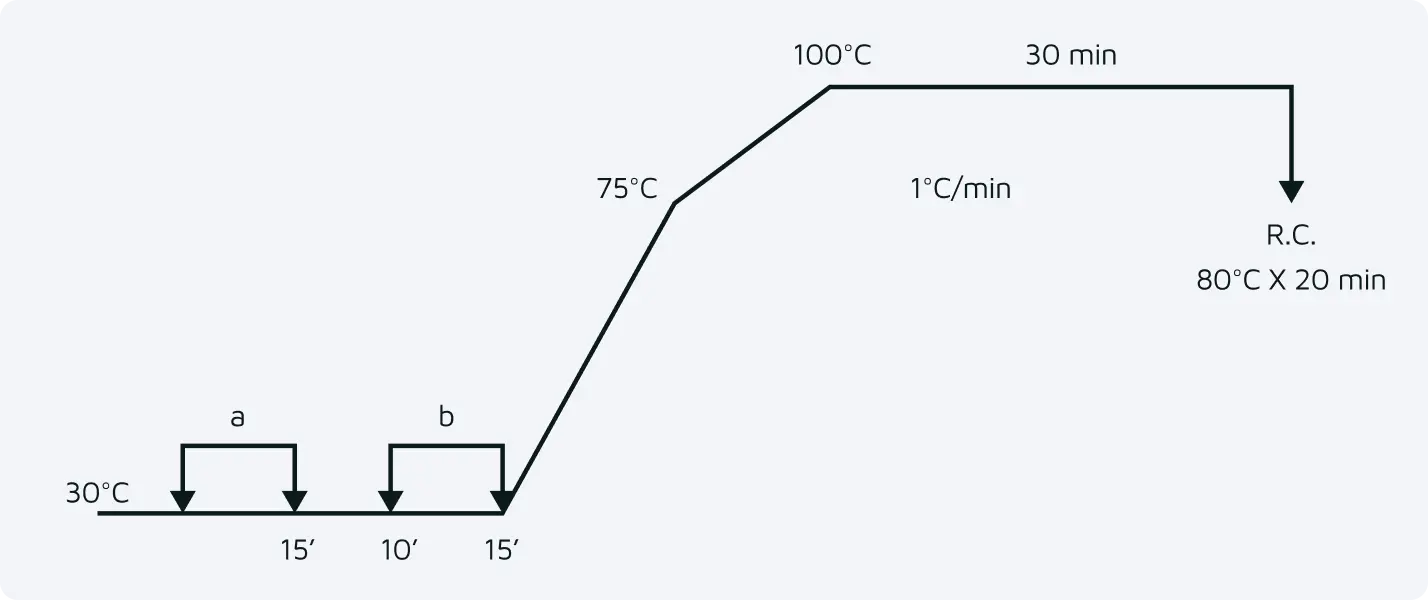

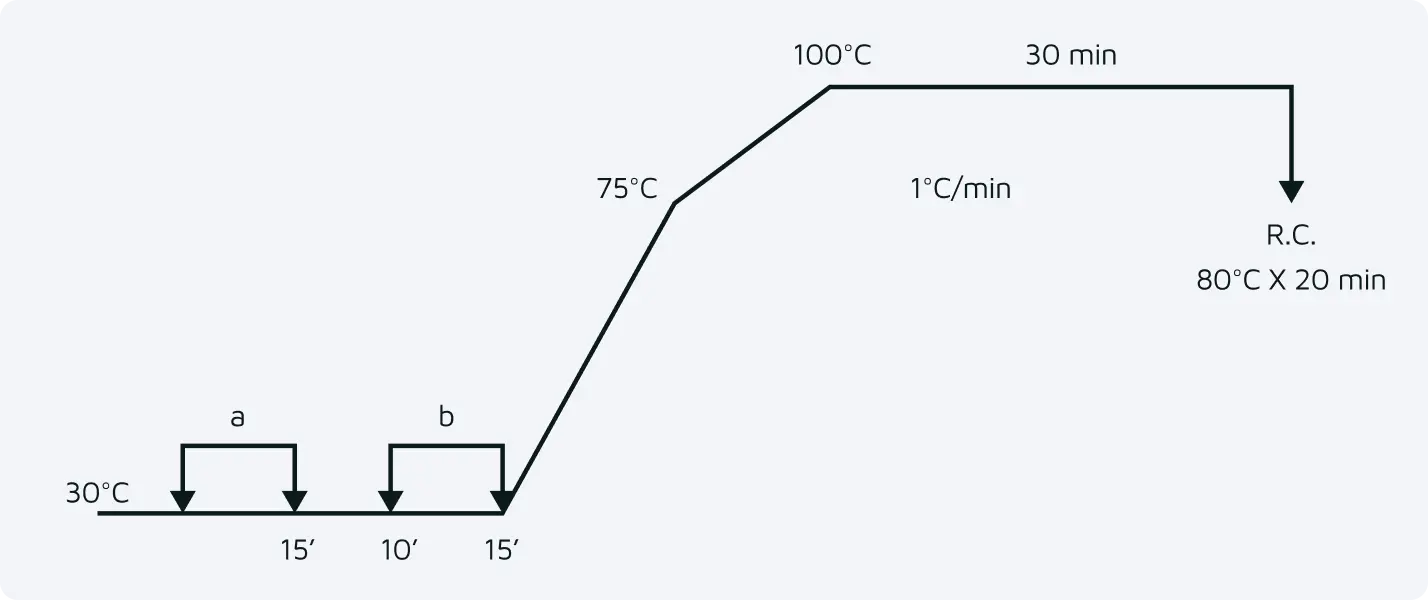

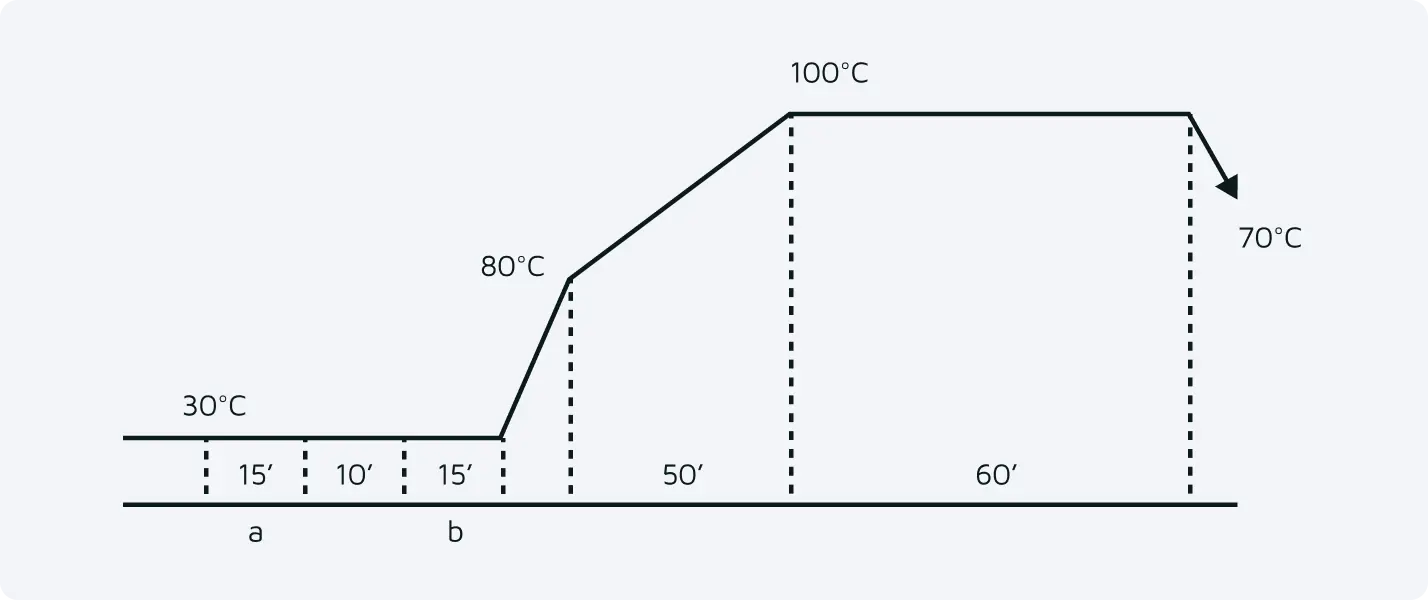

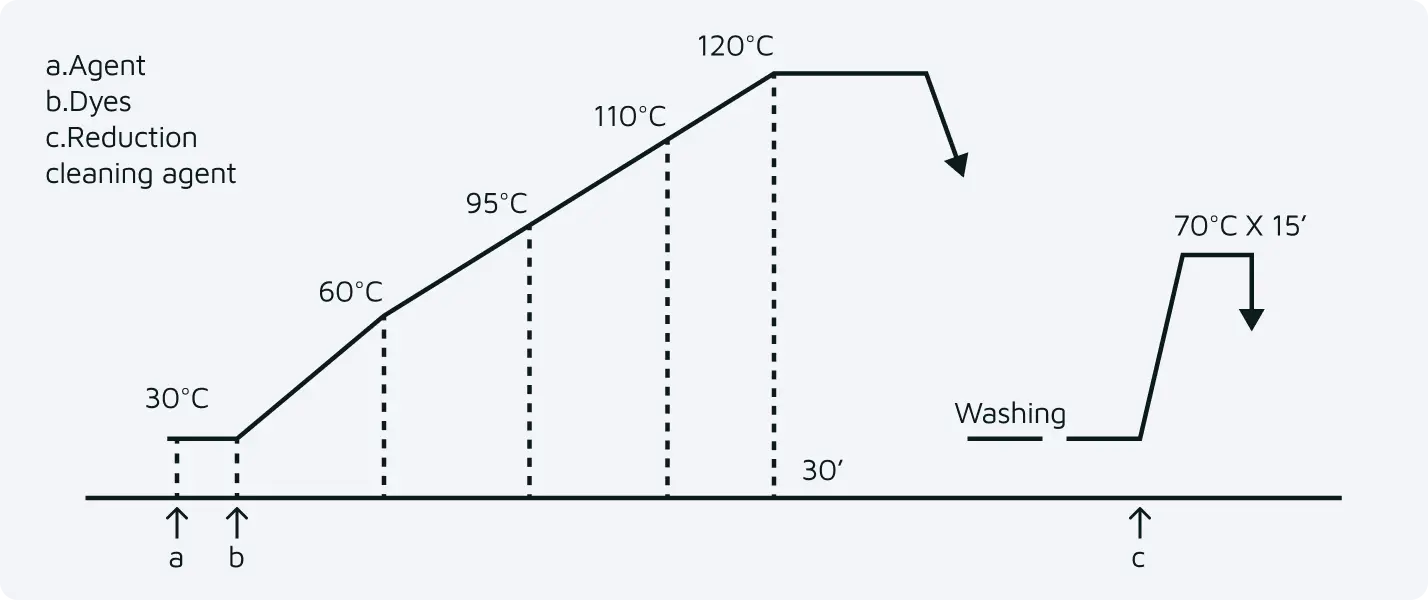

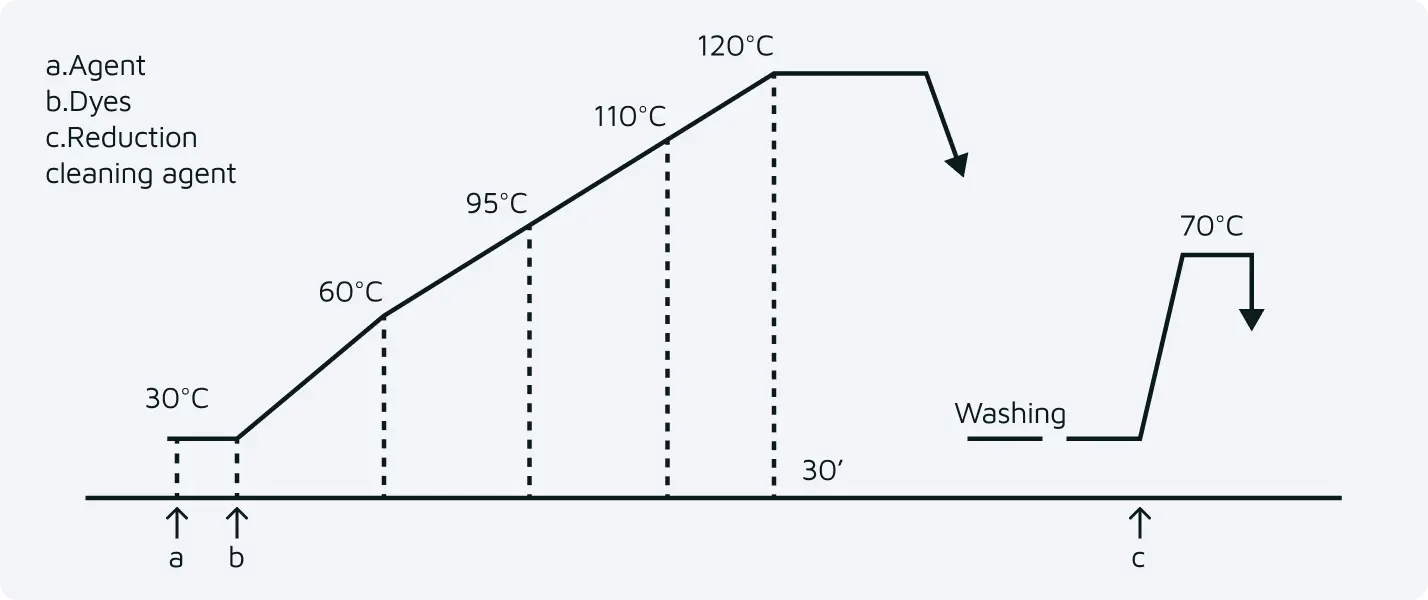

A. Carrier Dyeing Method

- Dyeacid pH=4.0 ~ 4.5 Taigal AF-806 (Dispersing and Levelling agent ) Taigal MN-T new ( Carrier)

- Taicron Dyes

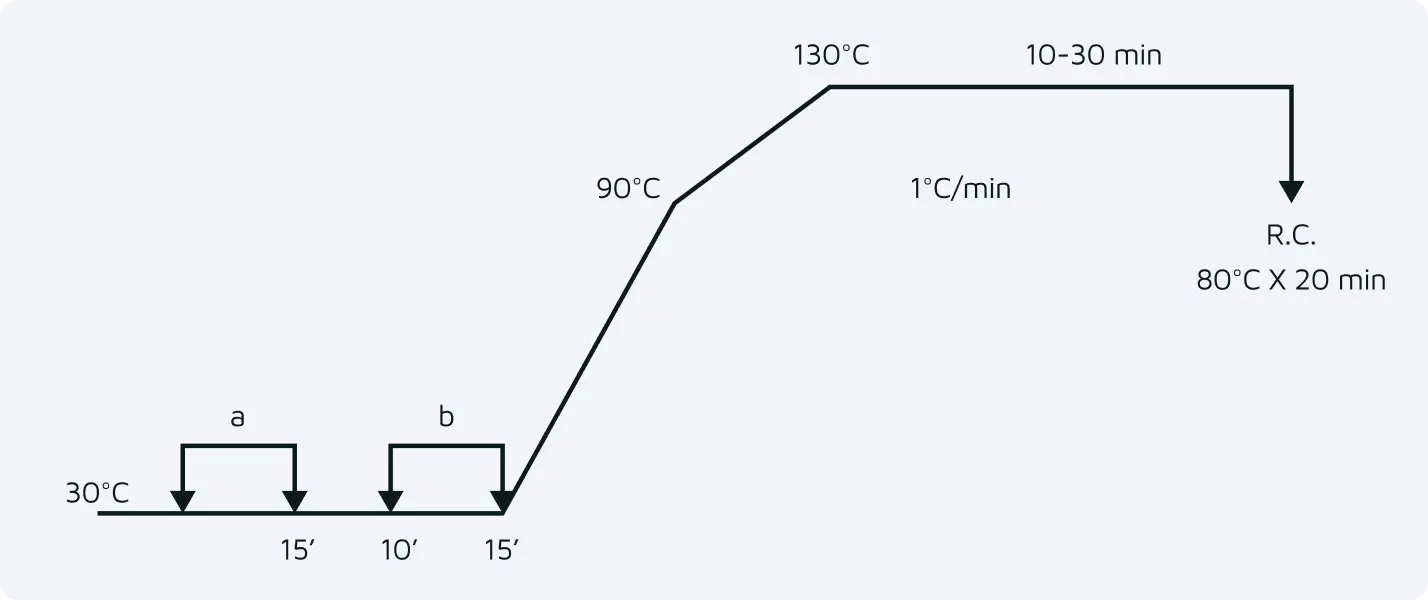

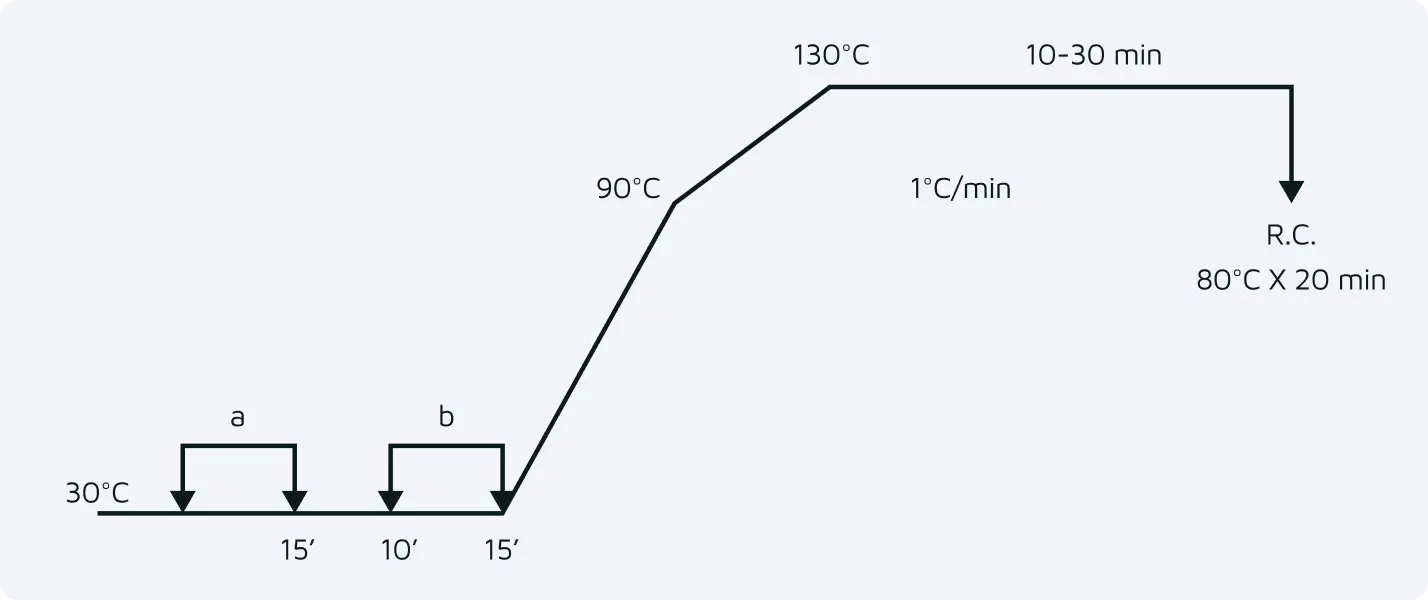

B. High Temperature Method

- Dyeacid pH-4.0 ~ 4.5 Taigal AF-806 (Dispersing and Levelling agent )

- Taicron Dyes

R.C. (Reduction Clean):

| Caustic Soda 45% | 2 g/l |

| Sodium Hydrosulfite | 3 g/l |

| Scourner BF-70N | 0.5-1 g/l |

C. Notes :

- It is suggested to dye with soft water, to avoid the metal ion influence the color shades.

- If the temperature of dispersions is over 50°C, it is possible that tarring may occur.

- The appropriate pH range for the application of disperse dyes is 4.0 to 4.5, and it should be controlled by buffers.

- The liquor should be cooled down to 90°C if additional shading is required, and then returned to 130°C dyeing again.

- Don’t cool down the temperature from 130°C rapidly, it may crease the fabrics and stiffen the touch and the look.

- The washing fastness of disperse dyes is absolutely related to the sublimation property.

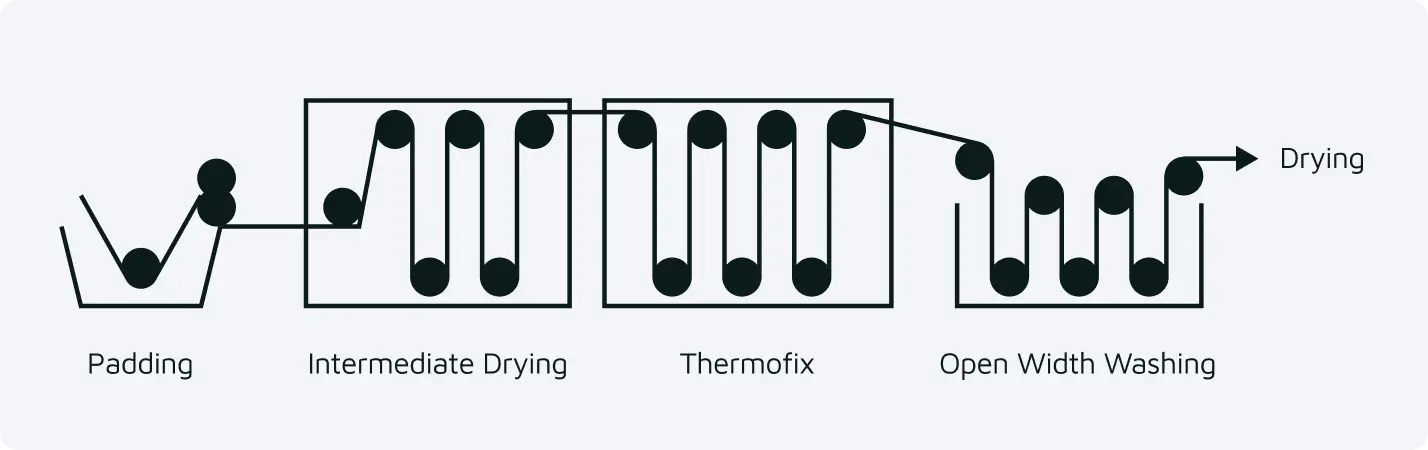

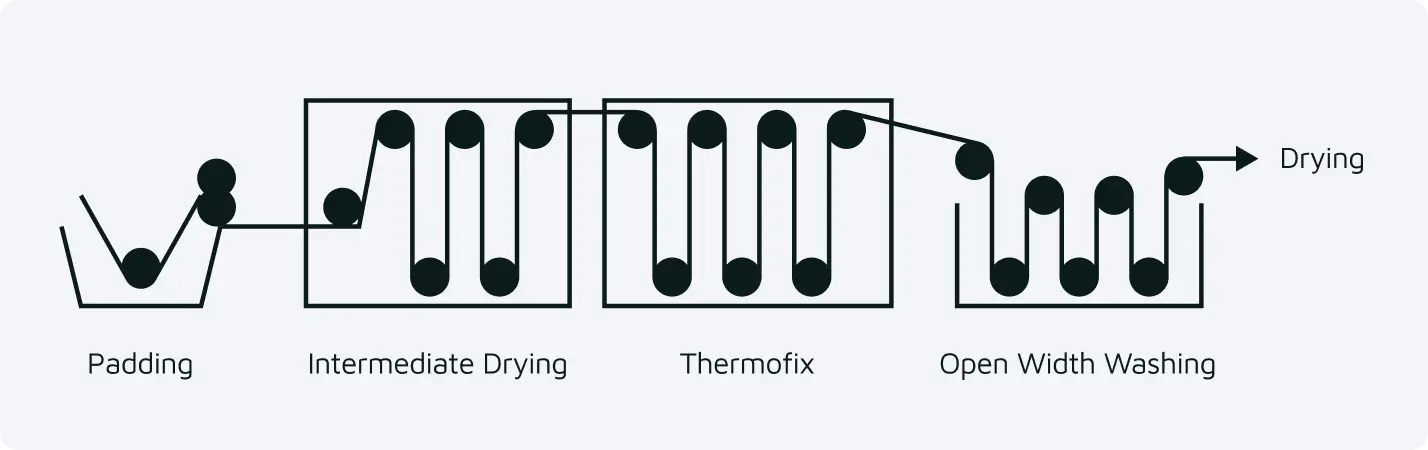

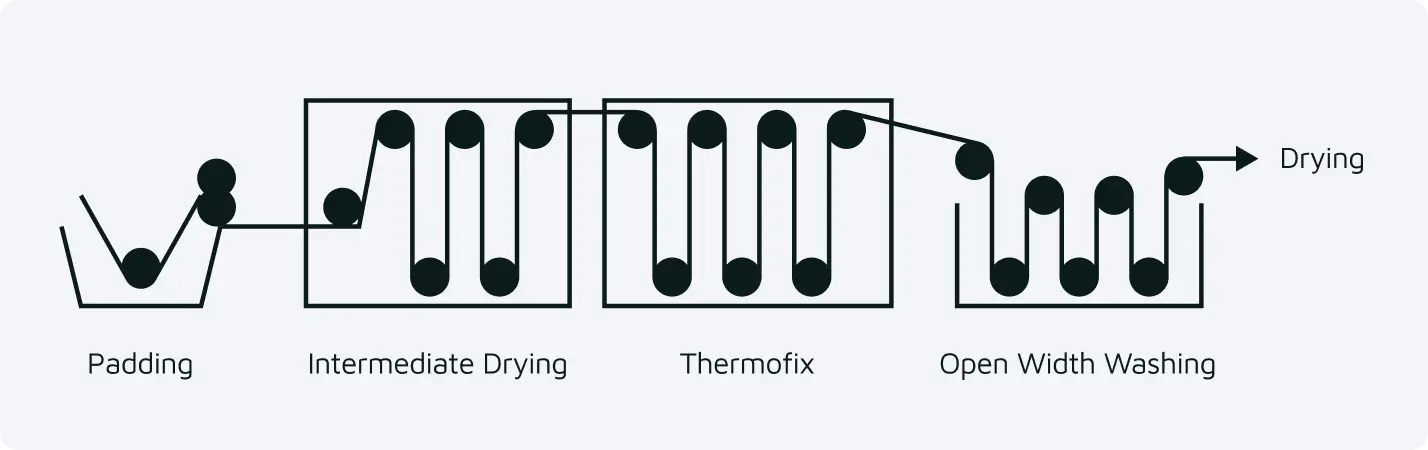

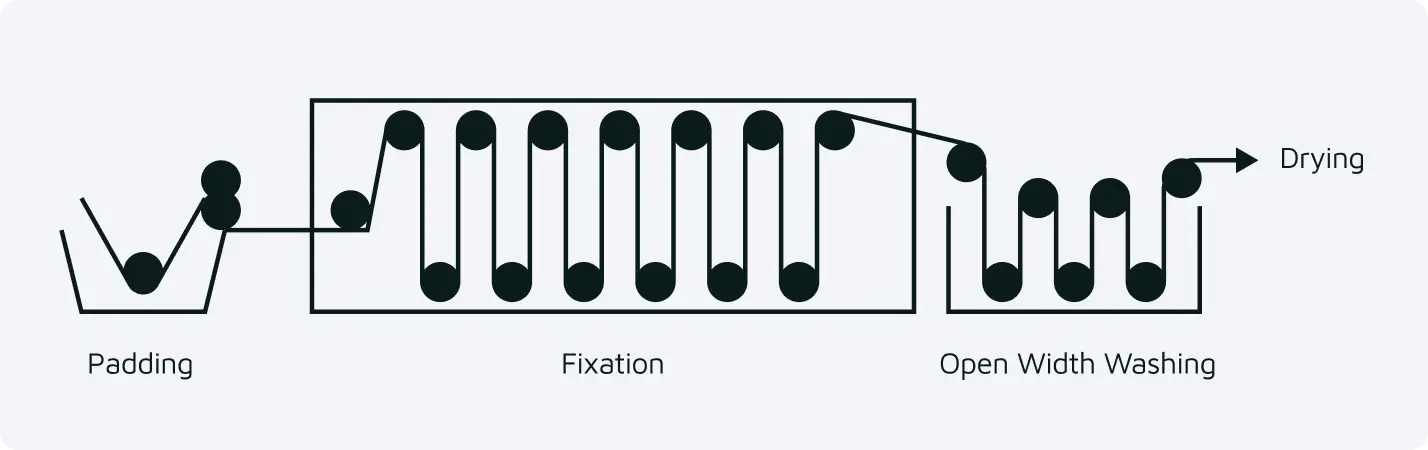

II. Continuous Dyeing

This method is suitable for high sublimation disperse dyes.

pick up = 50 ~ 60 %

- The material for padding should be thoroughly prepared.

- The composition of padding liquor:

Taicron Dyes X g/l Acetic acid pH= 4.0~4.5 Reduction inhibitor 1 g/l Wetting agent (when heavy fabrics are used) 1-2 g/l Migration inhibitor 1-2 g/l - The intermediate drying conditions are 110°C ~ 120°C X90 sec, the evenness of intermediate drying is influenced by the quality of final products.

- The theromfixation conditions are 200°C ~ 210°C X 1 min, the extent of thermofixation is very important for product’s fastness.

- The purpose of open width washer is to remove the unfixed to improve the fastness of products. The process of open width washer is as follows:

Ist box cold rising with overflow 2nd box cold rising 3rd box 50°C~ 60°C warm rising 4th box 70°C ~ 80°C soaping (nonionic soaping agent 1 g/l) 5th box – 7th box 80°C Reduction Clean

Caustic Soda (45% ) 2 g/l

Sodium Hydrosulfite 3 g/l

Scourner BF-70N 1 g/l8th box neutralizing 9th box cold rising

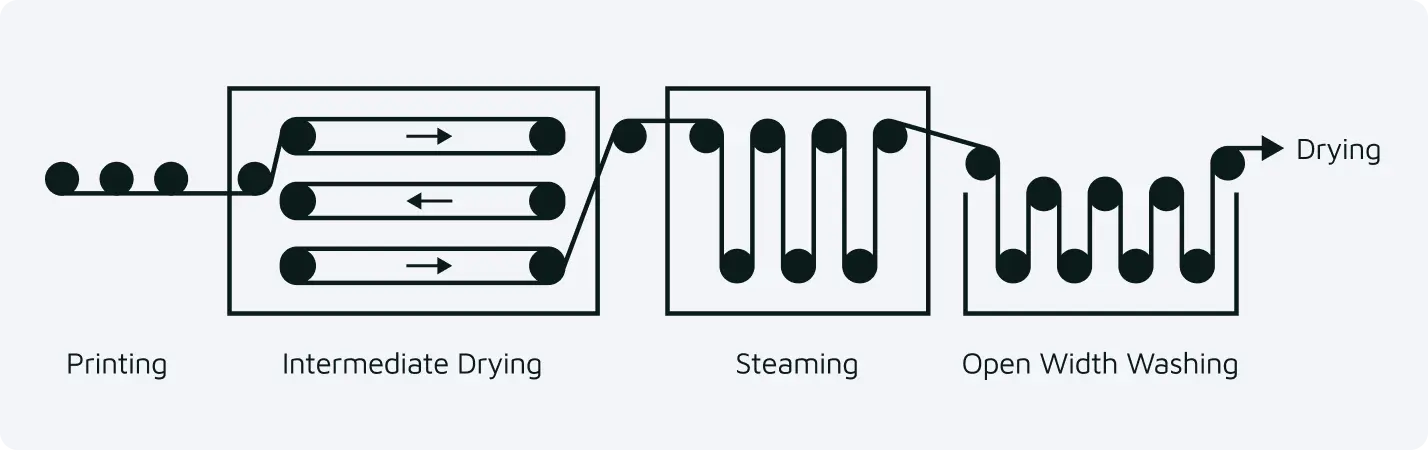

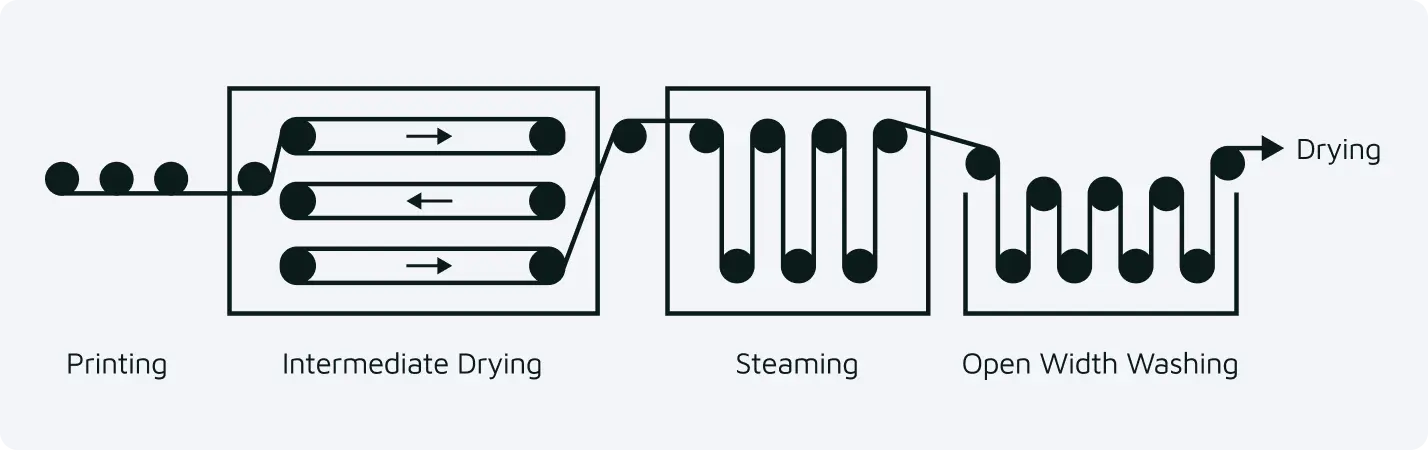

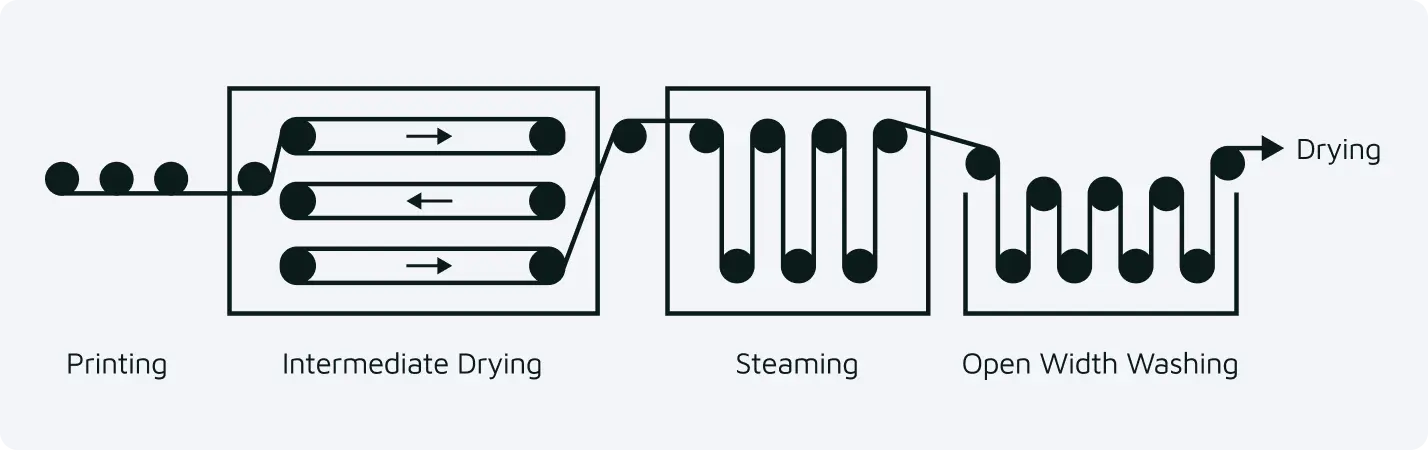

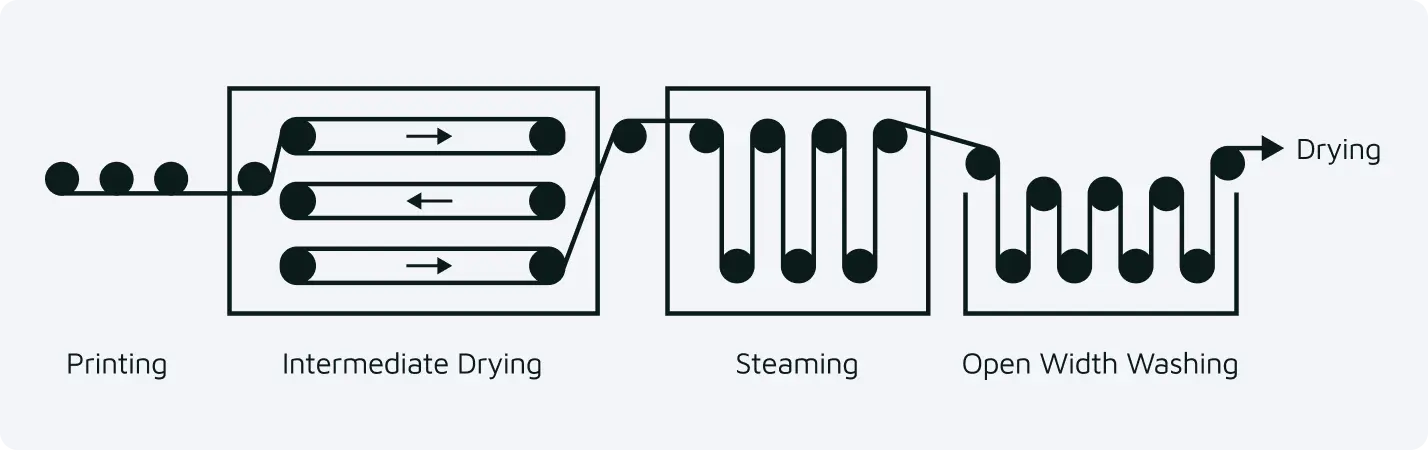

III. Printing

A. Direct Printing

a. Direct printing paste recipe (o.w.p)

| Taicron Dyes | X% |

| Warm water ( 40°C ~ 50°C ) | |

| Tartaric acid | pH=4.0-4.5 |

| Reduction inhibitor | 1.0% |

| Taigal AF-806 | 1.0% |

| Guar gum (Taigal AF-806: Dispersing / Levelling agent) | Y% |

b. Direct printing process

Printing → Intermediate Drying → Steaming → Open Width Washing → Drying

B. Discharge printing with reducing agent

a. Recipe (Taigal AF-806: dispersing and levelling agent):

| Composition | White Discharge | Color Discharge | ||

| White | Over print | Color | Over print | |

| Undischargeable dyes | ⎯ | ⎯ | X | ⎯ |

| Dischargeable dyes | ⎯ | X | ⎯ | X |

| Warm water (40°C – 50°C) | ⎯ | ⎯ | ⎯ | ⎯ |

| Urea | 2 | ⎯ | 4 | ⎯ |

| Dicyandiamide | 3 | ⎯ | 3 | ⎯ |

| Tartaric acid | 2 | 0.2 | ⎯ | 0.2 |

| SnCl2•2H20 | 8-15 | ⎯ | 8-12 | ⎯ |

| Reduction inhibitor | ⎯ | 0.3 | ⎯ | 0.3 |

| Taigal AF-806 | ⎯ | 0.5 | 0.5 | 0.5 |

| Guar gum (10%) | Y | Y | Y | Y |

b. Process:

Printing (Undischargeable dyes and discharge / resist agent) → Over printing (Dischargeable dyes) → Intermediate drying → Steaming → Open width washing → Drying

C. Notes:

- To make even penetration of material, the material should be prepared, and check the remainder of spin oil, oligomer and alkali before printing. Especially, the alkali will influence the color’s quality of polyester.

- Homogeneous stock thickening is prepared after standing overnight in order to eliminate air bubbles and to stabilize the viscosity of the print paste.

- The viscosity of print paste varies with the printing process and the form of material.

- The PH of printing paste is adjusted with non-volatile organic acids. For example, tartaric acid.

- The conditions of intermediate drying are 110°C ~ 120°C by hot flue dryer.

- Generally, the fixation is carried out by high temperature steaming (HTS) or high pressure steaming (HPS). The condition is as follows:

HTS – 170°C ~180°C x 7 ~ 10 min

HPS – 130°C x 30 min - The purpose of open width washer is to remove the unfixed paste and to improve the fastness of products. The process of open width washer is as follows:

Ist box cold rising with overflow 2nd box cold rising 3rd box 40°C~ 50°C warm rising 4th box 70°C ~ 80°C soaping

Antistaining agent 1-3 g/l5th box – 7th box 80°C Reduction Clean

Caustic Soda (43% ) 2 g/l

Sodium Hydrosulfite 3 g/l

Antistaining agent 1-3 g/l8th box neutralizing 9th box cold rising with overflow

The information and data given herein are based on accurate laboratory researches. They are used for guidance only. We cannot, however, accept any responsibility for the results obtained, in view of the numerous factors of applications are beyond our control. Our guarantee is limited to consistent quality of our products.

Taicron XF, SP Series

I. Exhaustion Dyeing

After the fabrics are prepared, the dyestuffs and dyeing auxiliaries are moved into the dyeing machine. There are two methods shown as follows which can be chosen:

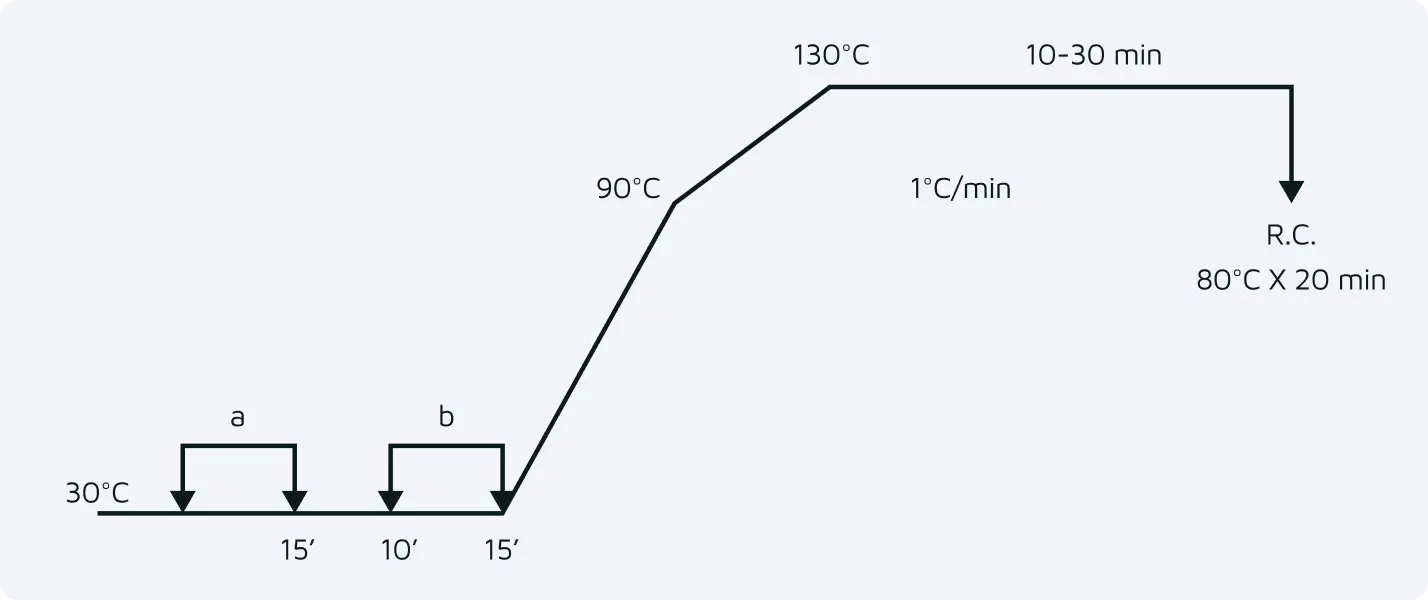

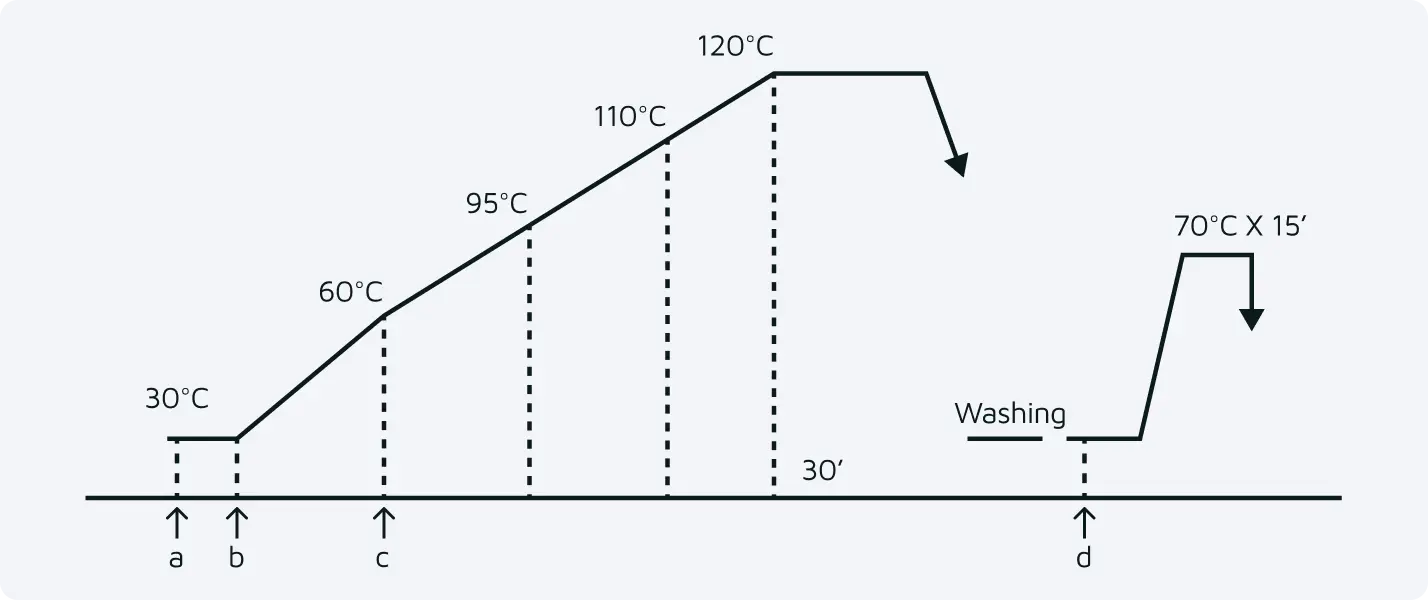

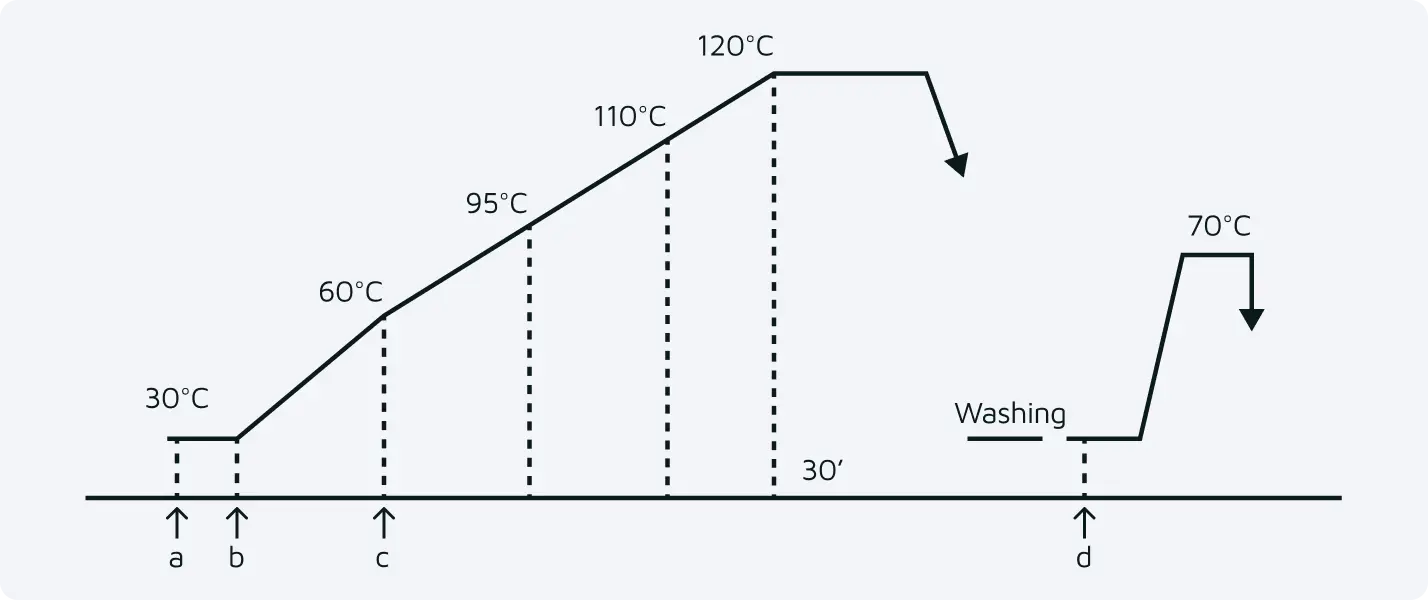

A. Carrier Dyeing Method

- Dyeacid HP pH=4.0 ~ 4.5

Taigal AF-806 (Dispersing and Levelling agent )

Taigal MN-T ( Carrier) - Taicron Dyes

B. High Temperature Method

- Dyeacid HP pH=4.0 ~ 4.5

Taigal AF-806 (Dispersing and Levelling agent ) - Taicron Dyes

R.C. (Reduction Clean):

| Caustic Soda 45% | 2 g/l |

| Sodium Hydrosulfite | 3 g/l |

| Scourner RCSN | 0.5-1 g/l |

C. Notes :

- It is suggested to dye with soft water, to avoid the metal ion influence the color shades.

- If the temperature of dispersions is over 50°C it is possible that tarring may occur.

- The appropriate pH range for the application of disperse dyes is 4.0 to 4.5, and it should be controlled by buffers.

- The liquor should be cooled down to 90°C if additional shading is required, and then returned to 130°C dyeing again.

- Don’t cool down the temperature from 130°C rapidly, it may crease the fabrics and stiffen the handle and the look.

- The washing fastness of disperse dyes is absolutely related to the sublimation property.

II. Continuous Dyeing

This method is suitable for high sublimation disperse dyes.

pick up = 50 ~ 60 %

- The material for padding should be thoroughly prepared.

- The composition of padding liquor:

Taicron Dyes X g/l Acetic acid pH= 4.0~4.5 Reduction inhibitor 1 g/l Wetting agent (when heavy fabrics are used) 1-2 g/l Migration inhibitor 1-2 g/l - The intermediate drying conditions are 110°C ~ 120°C, 90 sec, the evenness of intermediate drying is influenced by the quality of final products.

- The theromfixation conditions are 200°C ~ 210°C, 1 min, the extent of thermofixation is very important for product’s fastness.

- The purpose of open width washer is to remove the unfixed dyes to improve the fastness of products. The process of open width washer is as follows:

Ist box cold rising with overflow 2nd box cold rising 3rd box 50°C~ 60°C warm rising 4th box 70°C ~ 80°C soaping (nonionic soaping agent 1 g/l) 5th box – 7th box 80°C Reduction Clean

Caustic Soda (45% ) 2 g/l

Sodium Hydrosulfite 3 g/l

Scourner BF-70N 1 g/l8th box neutralizing 9th box cold rising

III. Printing

A. Direct Printing

a. Direct printing paste recipe (o.w.p)

| Taicron Dyes | X% |

| Warm water ( 40°C ~ 50°C ) | |

| Tartaric acid | pH=4.0-4.5 |

| Reduction inhibitor | 1.0% |

| Taigal AF-806 | 1.0% |

| Guar gum (Taigal AF-806: Dispersing / Levelling agent) | Y% |

b. Direct printing process

Printing → Intermediate Drying → Steaming → Open Width Washing → Drying

B. Discharge printing with reducing agent

a. Recipe (Taigal AF-806: dispersing and levelling agent):

| Composition | White Discharge | Color Discharge | ||

| White | Over print | Color | Over print | |

| Undischargeable dyes | ⎯ | ⎯ | X | ⎯ |

| Dischargeable dyes | ⎯ | X | ⎯ | X |

| Warm water (40°C – 50°C) | ⎯ | ⎯ | ⎯ | ⎯ |

| Urea | 2 | ⎯ | 4 | ⎯ |

| Dicyandiamide | 3 | ⎯ | 3 | ⎯ |

| Tartaric acid | 2 | 0.2 | ⎯ | 0.2 |

| SnCl2•2H20 | 8-15 | ⎯ | 8-12 | ⎯ |

| Reduction inhibitor | ⎯ | 0.3 | ⎯ | 0.3 |

| Taigal AF-806 | ⎯ | 0.5 | 0.5 | 0.5 |

| Guar gum (10%) | Y | Y | Y | Y |

b. Process:

Printing (Undischargeable dyes and discharge / resist agent) → Over printing (Dischargeable dyes) → Intermediate drying → Steaming → Open width washing → Drying

C. Notes:

- To make even penetration of material, the material should be prepared, and check the remainder of spin oil, oligomer and alkali before printing. Especially, the alkali will influence the color’s quality of polyester.

- Homogeneous stock thickening is prepared after standing overnight in order to eliminate air bubbles and to stabilize the viscosity of the print paste.

- The viscosity of print paste varies with the printing process and the form of material.

- The pH of printing paste is adjusted with non-volatile organic acids, for example, tartaric acid.

- The conditions of intermediate drying are 110°C ~ 120°C by hot flue dryer.

- Generally, the fixation is carried out by high temperature steaming (HTS) or high pressure steaming (HPS). The condition of them is as follows:

HTS – 170 C ~ 180°C x 7 ~ 10 min

HPS – 130°C x 30 min - The purpose of open with washer is to remove the paste and unfixed dyes to improve the fastness of products. The process of open width washer is as follows:

Ist box cold rising with overflow 2nd box cold rising 3rd box 40°C~ 50°C warm rising 4th box 70°C ~ 80°C soaping

Antistaining agent 1-3 g/l5th box – 7th box 80°C Reduction Clean

Caustic Soda (43% ) 2 g/l

Sodium Hydrosulfite 3 g/l

Antistaining agent 1-3 g/l8th box neutralizing 9th box cold rising with overflow

The information and data given herein are based on accurate laboratory researches. They are used for guidance only. We cannot, however, accept any responsibility for the results obtained, in view of the numerous factors of applications are beyond our control. Our guarantee is limited to consistent quality of our products.

Taicron Luminous, HW-T, E-ACT, SE-UNT Series

I. Exhaustion Dyeing

After the fabrics are prepared, the dyestuffs and dyeing auxiliaries are moved into the dyeing machine. There are two methods shown as follows which can be chosen:

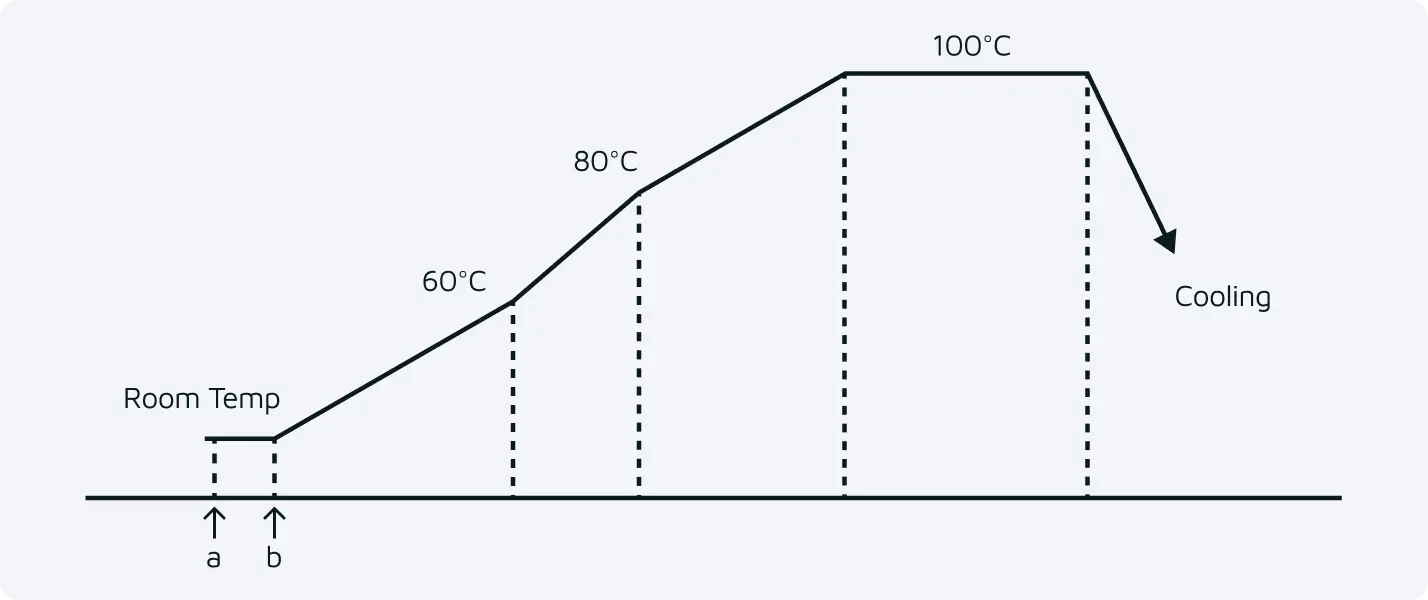

A. Carrier Dyeing Method

- Dyeacid HP pH=4.0 ~ 4.5

Taigal AF-806 (Dispersing and Levelling agent )

Taigal MN-T ( Carrier) - Taicron Dyes

B. High Temperature Method

- Dyeacid HP pH=4.0 ~ 4.5

Taigal AF-806 (Dispersing and Levelling agent ) - Taicron Dyes

R.C. (Reduction Clean):

| Caustic Soda 45% | 2 g/l |

| Sodium Hydrosulfite | 3 g/l |

| Scourner RCSN | 0.5-1 g/l |

C. Notes :

- It is suggested to dye with soft water, to avoid the metal ion influence the color shades.

- If the temperature of dispersions is over 50°C ,it is possible that tarring may occur.

- The appropriate pH range for the application of disperse dyes is 4.0 to 4.5, and it should be controlled by buffers.

- The liquor should be cooled down to 90°C if additional shading is required, and then returned to 130°C dyeing again.

- Don’t cool down the temperature from 130°C rapidly, it may crease the fabrics and stiffen the handle and the look.

- The washing fastness of disperse dyes is absolutely related to the sublimation property.

II. Continuous Dyeing

This method is suitable for high sublimation disperse dyes.

pick up = 50 ~ 60 %

- The material for padding should be thoroughly prepared.

- The composition of padding liquor:

Taicron Dyes X g/l Acetic acid pH= 4.0~4.5 Reduction inhibitor 1 g/l Wetting agent (when heavy fabrics are used) 1-2 g/l Migration inhibitor 1-2 g/l - The intermediate drying conditions are 110°C ~ 120°C, 90 sec, the evenness of intermediate drying is influenced by the quality of final products.

- The theromfixation conditions are 200°C ~ 210°C, 1 min, the extent of thermofixation is very important for product’s fastness.

- The purpose of open width washer is to remove the unfixed dyes to improve the fastness of products. The process of open width washer is as follows:

Ist box cold rising with overflow 2nd box cold rising 3rd box 50°C~ 60°C warm rising 4th box 70°C ~ 80°C soaping (nonionic soaping agent 1 g/l) 5th box – 7th box 80°C Reduction Clean

Caustic Soda (45% ) 2 g/l

Sodium Hydrosulfite 3 g/l

Scourner BF-70N 1 g/l8th box neutralizing 9th box cold rising

III. Printing

A. Direct Printing

a. Direct printing paste recipe (o.w.p)

| Taicron Dyes | X% |

| Warm water ( 40°C ~ 50°C ) | |

| Tartaric acid | pH=4.0-4.5 |

| Reduction inhibitor | 1.0% |

| Taigal AF-806 | 1.0% |

| Guar gum (Taigal AF-806: Dispersing / Levelling agent) | Y% |

b. Direct printing process

Printing → Intermediate Drying → Steaming → Open Width Washing → Drying

B. Discharge printing with reducing agent

a. Recipe (Taigal AF-806: dispersing and levelling agent):

| Composition | White Discharge | Color Discharge | ||

| White | Over print | Color | Over print | |

| Undischargeable dyes | ⎯ | ⎯ | X | ⎯ |

| Dischargeable dyes | ⎯ | X | ⎯ | X |

| Warm water (40°C – 50°C) | ⎯ | ⎯ | ⎯ | ⎯ |

| Urea | 2 | ⎯ | 4 | ⎯ |

| Dicyandiamide | 3 | ⎯ | 3 | ⎯ |

| Tartaric acid | 2 | 0.2 | ⎯ | 0.2 |

| SnCl2•2H20 | 8-15 | ⎯ | 8-12 | ⎯ |

| Reduction inhibitor | ⎯ | 0.3 | ⎯ | 0.3 |

| Taigal AF-806 | ⎯ | 0.5 | 0.5 | 0.5 |

| Guar gum (10%) | Y | Y | Y | Y |

b. Process:

Printing (Undischargeable dyes and discharge / resist agent) → Over printing (Dischargeable dyes) → Intermediate drying → Steaming → Open width washing → Drying

C. Notes:

- To make even penetration of material, the material should be prepared, and check the remainder of spin oil, oligomer and alkali before printing. Especially, the alkali will influence the color’s quality of polyester.

- Homogeneous stock thickening is prepared after standing overnight in order to eliminate air bubbles and to stabilize the viscosity of the print paste.

- The viscosity of print paste varies with the printing process and the form of material.

- The pH of printing paste is adjusted with non-volatile organic acids, for example, tartaric acid.

- The conditions of intermediate drying are 110°C ~ 120°C by hot flue dryer.

- Generally, the fixation is carried out by high temperature steaming (HTS) or high pressure steaming (HPS). The condition of them is as follows:

HTS – 170 C ~ 180°C x 7 ~ 10 min

HPS – 130°C x 30 min - The purpose of open with washer is to remove the paste and unfixed dyes to improve the fastness of products. The process of open width washer is as follows:

Ist box cold rising with overflow 2nd box cold rising 3rd box 40°C~ 50°C warm rising 4th box 70°C ~ 80°C soaping

Antistaining agent 1-3 g/l5th box – 7th box 80°C Reduction Clean

Caustic Soda (43% ) 2 g/l

Sodium Hydrosulfite 3 g/l

Antistaining agent 1-3 g/l8th box neutralizing 9th box cold rising with overflow

The information and data given herein are based on accurate laboratory researches. They are used for guidance only. We cannot, however, accept any responsibility for the results obtained, in view of the numerous factors of applications are beyond our control. Our guarantee is limited to consistent quality of our products.

Taiacryl Series

Taiacryl Dyes, marked by T&T Industries Corporation, are cationic dyes for dyeing acrylic fibers; applicable to exhaustion dyeing, continuous dyeing and printing, etc. They have brilliant shades, excellent fastness and very good build-up property.

The characteristics of Taiacryl Dyes are as follows :

1. The Relative Saturation Value (F Value) of acrylie fiber

The polyacrylonitrile fiber contains a limited number of acidic radical, and this acidic radical forms ionic bond with cationic dyes. Following Table shows the relative saturation value (F value ) of various acrylic fibers.

| Tarde mark | F value |

| Vonnel 17 | 1.2 |

| Exlan DK | 2.3 |

| Cashmilon F | 1.9 |

| Beslon W | 2.1 |

| Toraylon | 3.2 |

| Tairyal E-20-F | 2 |

| Tofalon | 1.4 |

| Texlon | 1.8 |

In general, the maximun ion linked amount of pure Malachite Green is determined and this is regarded as the relative saturation value of acrylic fiber.

2. “f value” of Taiacryl Dyes

f value of Taiacryl Dyes, which is called saturation factor, is a constant of individual dye and can be calculated from the following formula.

[math]\text{f value} =\dfrac{\text{F (Relative saturation value of acrylic fiber)}}{\text{S (Saturation dyeing % of each Taiacryl Dyes)}}[/math]

S can be obtained experimentally and means the maximum percentage of the absorbable dyestuff on the weight of the fiber (o.w.f. %).

3. D.C. value ( Dyeing Constant)

The D.C. value varies depending on the fiber and the dyeing conditions. The optimum D.C. value of each machine is shown as following:

| Rotary beck dyeing (hank dyeing machine in suspension) | 80 ~ 90% |

| Package dyeing | 60 ~ 80% |

| Winch dyeing | 80 ~ 90% |

4. The optimum amount of cationic retarder

Cationic retarders should be used in the optimum amount to ensure the moderate absorption of Taiacryl Dyes and moreover perfect dye-absorption at the end of dyeing.

[math]\text{Amount of Retarder (% o.w.f. )} =\dfrac{\text{(F value x DC) – [Sum of (amount of Dyesix f value)] }}{\text{f value of Retarder}}[/math]

5. Combination number (K-value )

The K-value serves as a guide to the combination of the catte

dyes, when dyed on a particular acrylic fiber. If dyes with different K value are combined, the dyes with lower value is taken up by the fiber before that with higher value.

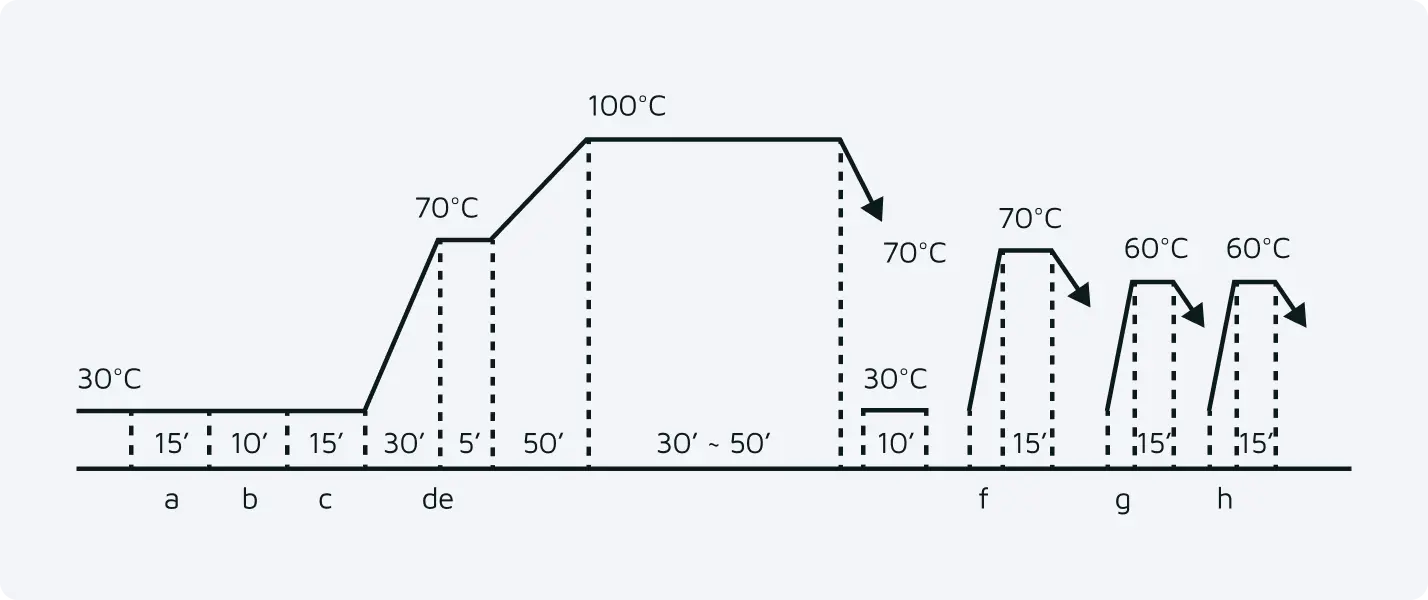

I. Exhaustion Dyeing

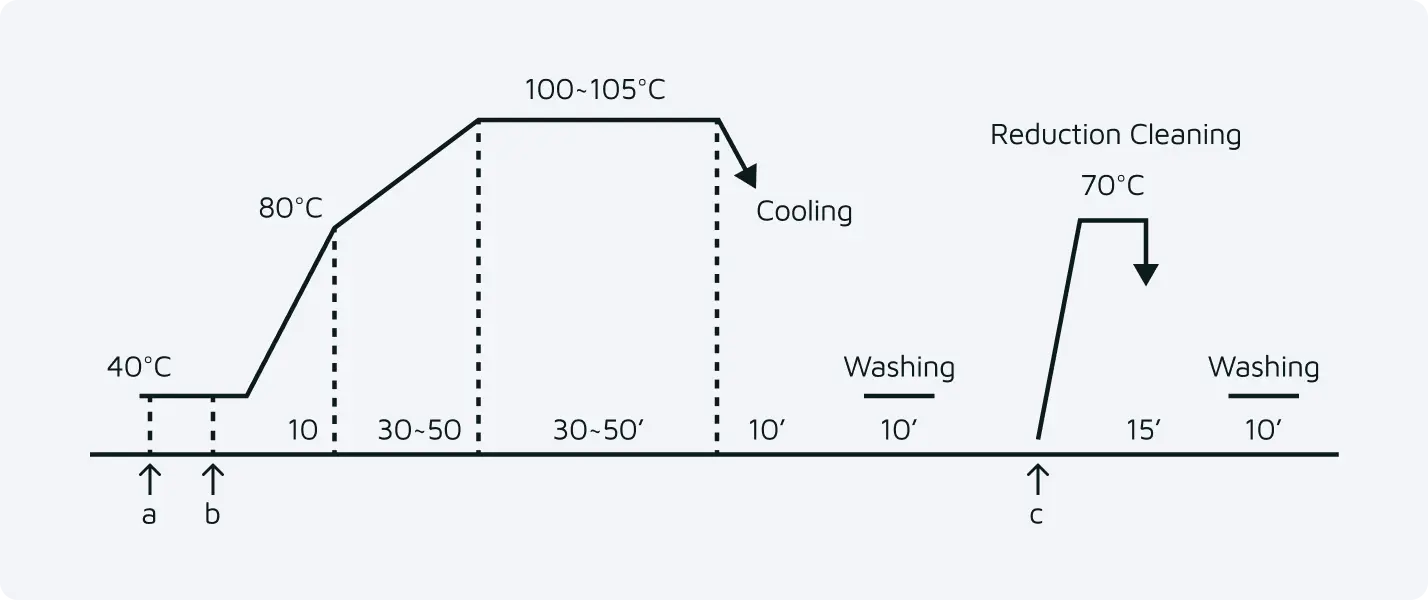

◎ For 100% Acrylic Fibers

Fiber Buffer pH= 4.0 ~ 4.5 Taigal PAN (Retarding agent of Taiacryl Dyes) Taigal AN Conc New (Levelling agent of Taiacryl Dyes) 0.5 – 1.0% o.w.f. - Taiacryl Dyes

◎ For Acrylic Wool Blends

Fiber Taigal KPN (Anti-Precipitate agent ) 1.0 ~2.0 g/l Taigal NL-40H (Levelling agent for Taiacid Dyes) 0.5 ~ 1.0 % o.w.f. Scourner WN-T 0.5 ~ 1.0 % o.w.f. Buffer pH = 4.0 - Taiacid Dyes

Taigal PAN (Retarder for Taiacryl Dye) Taigal AN Conc New (Levelling agent for Taiacryl Dyes) 0.5 ~ 1.0 % o.w.f. - Taiacryl Dyes

Ammonia Water 28% 0.3 ~ 0.5 сс/1 Scourner WN-T 0.3 ~ 0.5 g/1 Dyefix N-600T (Fixing agent for Taiacid Dyes) 2.0 ~ 3.0 % o.w.f. Taisoft SSK-50 Base 1.0 ~ 3.0% o.w.f.

II. Continuous Dyeing

pick up = 50 ~ 100 %

- The material for padding should be throughly treated first.

- The composition of padding liquor:

Taiacryl Dyes X g/l Acetic acid pH= 4.5~5.0 Tartaric acid Nonionic wetting agent (for heavy fabrics usage) 1.0 ~ 2.0 g/l Nonionic migration inhibitor 1.0 ~ 2.0 g/l - The fixation conditions are 98°C~ 100°C, 20 ~ 60 min. The fixation time depends on the temperature, the type of fiber, the type of dye and its concentration, and on the concentration of padding auxiliaries.

- The purpose of open width washer is to remove the unfixed dyes to improve the fastness of products.

III. Printing

- Direct Printing recipe (o.w.p.)

Taiacryl Dyes X% Hot water Tartaric acid pH=4.0-4.5 Reduction inhibitor 1.0% Nonionic wetting agent 1.0% Guar gum Y% - The steaming conditions are 100°C ~ 102°C, 30 min by high pressure steaming.

- Be sure to use nononic detergent: ( suck as Saourner WN-T ) in the soaping process of Taiacryl dyed fabrics, to keep well fastness.

Explanation of Signification

- Light : Test colorfastness to light by JIS L0842 63°C X 40hrs Carbon Arc.

- Saliva: Test colorfastness to saliva by DIN 53160-1

- Rubbing : Test colorfastness to rubbing by ISO 105-X12

The information and data given herein based on accurate laboratory researches. They are used for guidance only. We cannot, however, accept any responsibility for the results obtained, in view of the numerous factors of applications are beyond our control. Our guarantee is limited to consistent quality of our products.

Taiacryl AD Series

1. Fundamental Properties

Taiacryl AD Colors are disperse – types with anionic character. Therefore, Taiacryl AD Colors can provide a great advantage in the dyeing of acrylic fiber blends or cationic dyeable polyester fiber and its blends, which can be quite compatible with other anionic compounds. Therefore, Taiacryl AD Colors are suitable for one bath one step dyeing.

2. Dissolving the Dyes

Dissolving the Taiacryl AD Colors with below 45°C water, while stirring to complete dissolution. (If the water over 50°C will destroy disperse-ability of dyes)

Remark : Pasting with acetic acid or alcohol and dissolving the dyes with steam should all be avoided.

3. Dyeing Process (Recipe)

3-1 Dyeing of Taiacryl AD on 100% CDP Fibre

| a. Dyeacid HP | pH 4 |

| b. Taiacryl AD dyes | X % o.w.f. |

3-2 Dyeing of Taiacryl AD on Polyester/CDP Blends

Fiber X kg Dyeacid HP pH 4.0~4.5 Scourner WN-T 0.5 ~ 1 g/l Taicron dyes Y % o.w.f. Taiacryl AD dyes Z % o.w.f. Sodium hydrosulfite 1~2 g/l Ammonia Water (NH328%) 1cc/1 or Na2CO3 0.3~0.5g/l Scourner WN-T 0.5~1 g/1

3-3 Dyeing of Taiacryl AD on Acrylic/ Wool Blends

Tainaset dyes X % o.w.f. Dyeacid HP pH 4.0~4.5 Taiacryl AD dyes Y % o.w.f.

3-4 Dyeing of Taiacryl AD on Polyester/Acrylic Blends

Fiber X kg Taicron dyes Y % o.w.f. Dyeacid HP pH 4.0~4.5 Taigal MN-T New 1~2 g/l Taiacryl AD dyes Z % o.w.f. Sodium hydrosulfite 1~2 g/l Na2CO3 0.3~0.5 g/l (limited) Scourner WN-T 0.5 ~ 1 g/l

Property of Taiacryl dyes

pH stability :

Dyebath is adjusted to a wide range of pH, shade of colors may be change when compared with standard condition (pH=4.5).

| Staining on other fibers | ISO 105-A03 |

| Fastness to light | JIS L0842 63°C x 40 hr Carbon Arc. |

| Fastness to Perspiration Fastness to Heat Setting | ISO 105-E04 |

| Fastness to Heat Setting | 170°C ×45″ |

| Fastness to Rubbing | 100 times |

| Fastness to Stock Sublimation | 120°C x 80 min |

| Fastness to Chlorine Water | ISO 105-E03 |

| Fastness to Chlorine Washing | ISO -105 C105 CO2 , AATCC 2А |

| CDP Fiber + Lycra | 100D/ 144F CD + Lycra12% |

Taiacryl CD Series

1.Fundamental Properties

Taiacryl CD Colors are specially selected from cationic dyes for dyeing of cationic dyeable polyester fibre with a good stability in high dyeing temperature at 120°C. Taiacryl CD Colors show a cationic character, therefore, Taiacryl CD Colors are not suitable for one bath one step dyeing with anionic compounds, unless Anti-precipitating agent is added during dyeing.

2. Dissolving the Dyes

The requisite amount of Taiacryl CD Colors is pasted with three times as much warm water (60°C),then sufficient hot water (95°C), about 20 times, is added with 1/3 amount of acetic acid 30% while stirring to complete dissolution.

3. Dyeing Process (Recipe)

3-1 Dyeing of Taiacryl CD on 100% CDP Fibre

| a. Taiacryl CD dyes | X % o.w.f. |

| b. Dyeacid HP | pH 4 |

3-2 Dyeing of Taiacryl AD on Polyester/CDP Blends

Fiber X kg Taigal CDP 0.5 ~ 2.0 g/l Dyeacid HP pH 4.0~4.5 Taicron dyes Y % o.w.f. Taiacryl CD dyes Z % o.w.f. Sodium hydrosulfite 1~2 g/l Ammonia Water (NH328%) 1 g/l or Na2CO3 0.3~0.5g/l Scourner WN-T 1 g/l

Property of Taiacryl dyes

pH stability :

Dyebath is adjusted to a wide range of pH, shade of colors may be change when compared with standard condition (pH-4.5).

| Staining on other fibers | ISO 105-A03 |

| Fastness to light | JIS L0842 63°C x 40 hr Carbon Arc. |

| Fastness to Perspiration Fastness to Heat Setting | ISO 105-E04 |

| Fastness to Heat Setting | 170°C ×45″ |

| Fastness to Rubbing | 100 times |

| Fastness to Stock Sublimation | 120°C x 80 min |

| Fastness to Chlorine Water | ISO 105-E03 |

| Fastness to Chlorine Washing | ISO -105 C105 CO2 , AATCC 2А |

| CDP Fiber + Lycra | 100D/ 144F CD + Lycra12% |